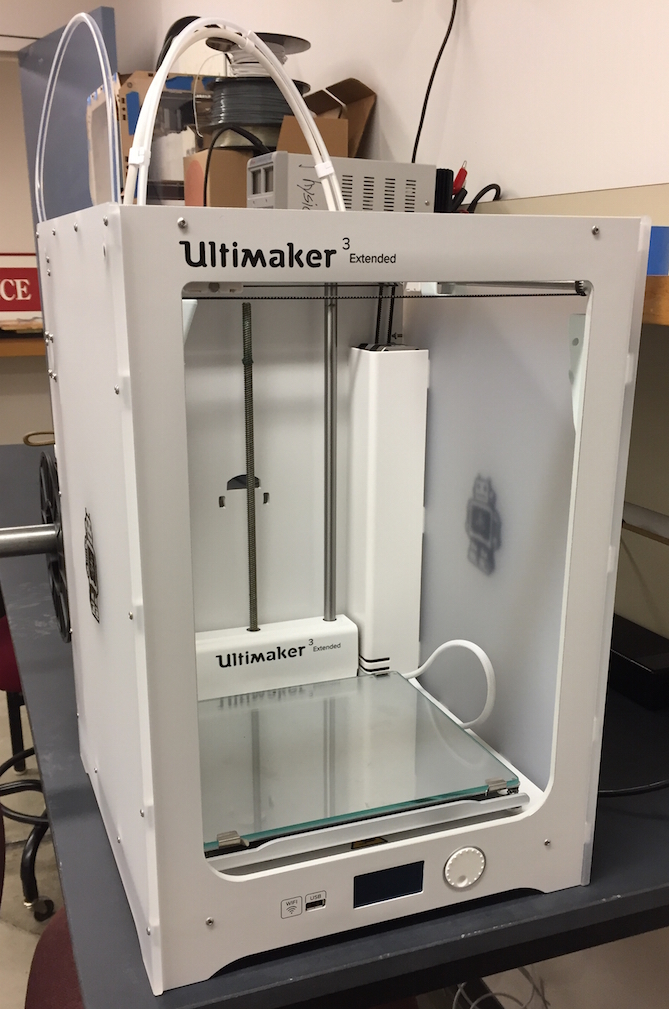

We purchased our Ultimaker 3 Extended in December 2016.

Here are some key specifications:

- Fused Filament Fabrication(FFF)/Fused Deposition Modeling (FDM) – filament is melted and extruded onto a build platform

- Material: Open platform, can print most available materials (PLA, ABS, Nylon, PETG, PVA, flexible TPU). We print mostly with PLA and use PVA as support material if needed.

- Dual Extruder: can print in two colors on same part or one color with dissolvable support material (PVA). Extruder temperature range is 180-280

- PVA support material is water soluable and will completely dissolve after soaking in water overnight.

- Heated Bed: improves adhesion for almost all materials, range is 20-100°C

- Build Volume: 8.5″ x 8.5″ x 11.8″ (single extruder), 7.8″x8.5″x11.8″ (dual extruder)

- Minimum Layer Thickness: 60 to 600 microns per layer using print cores with nozzle diameters of 0.250, 0.5, and 0.8mm.

- File Format: .stl or .obj

- Software: Cura (download here for free; select Ultimaker 3 Extended in settings)

- File transfer: USB stick for student prints

This printer is open to use by anyone at Reed (students, faculty, and staff). I have plenty of PLA filament ready to go so you just need a file and a desire to print to get started.