About the project

This exploratory learning project was inspired by a posting by a YouTube video by Desktop Makes who were examining how to create the physical visual representation of audio waveforms.

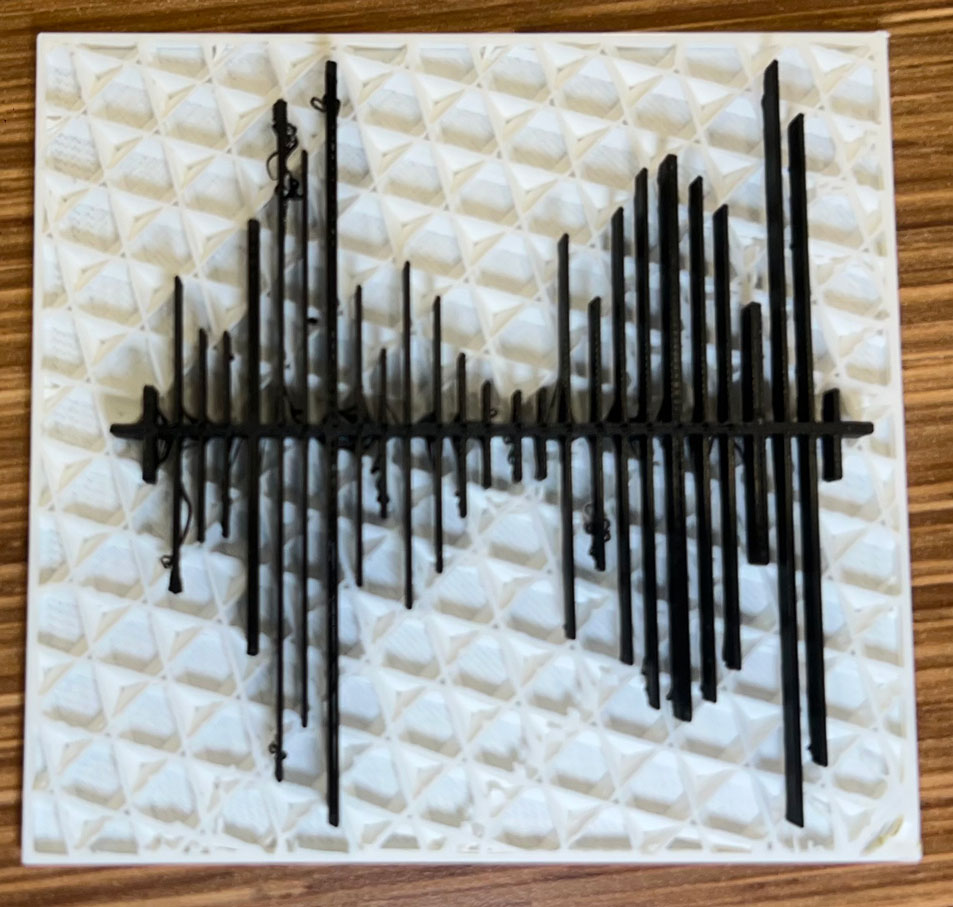

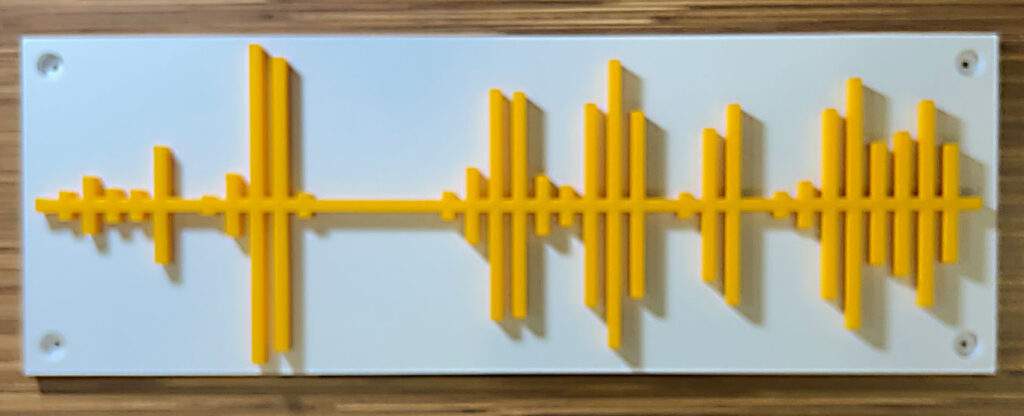

Instructional Technology Service staff and their student workers (aka mLabbies) chose a few inspirational quotes, and found an audio recording of each quote. Afterwards, 3d models of the waveform were created from the quotes, then printed out.

The quotes

- I have a dream – Martin Luther King, Jr.

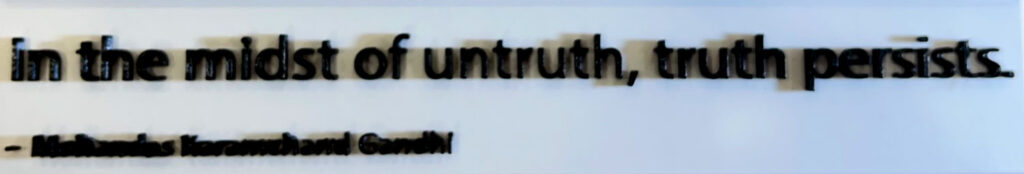

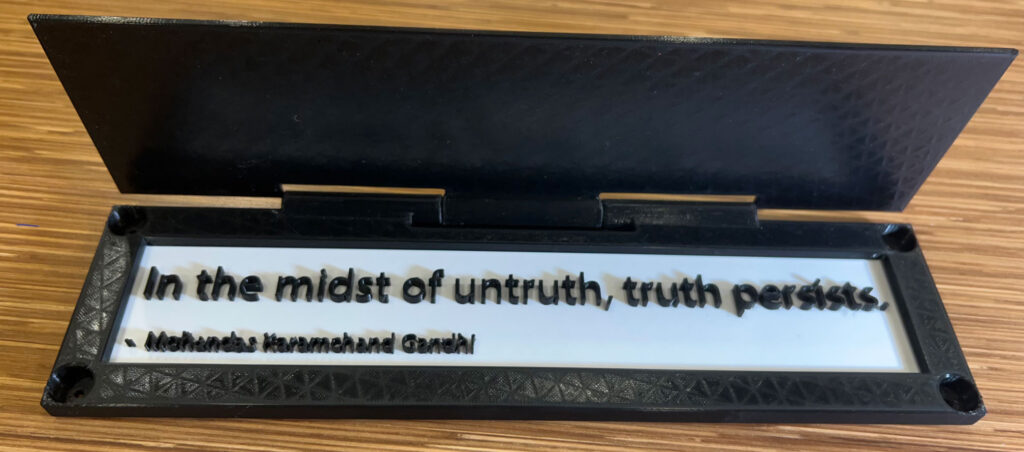

- In the midst of untruth, truth persists – Mahatma Gandhi

- One small step for a man, one giant leap for mankind – Neil Armstrong

- And where we are met with cynicism and doubt and those who tell us that we can’t, we will respond with that timeless creed that sums up the spirit of a people: Yes, we can – Barack Obama

Learning outcomes

mLabbies used a variety of different software programs to create and modify 3d models, which would deepen their knowledge and experience computer aided design (CAD) and modeling practices for 3d printing.

The mlabbies also expanded their expertise with using the 3d printers in the Digital Fabs space here at Reed College.

The (exploratory) process

The project explored how to visually represent a waveform using some of the technologies available in the Digital Fab space here at= Reed College, which included a laser printer and 3d printers. The Desktop Makes video provided one approach to represent an audio waveform as the students explored how to create and physically display the models.

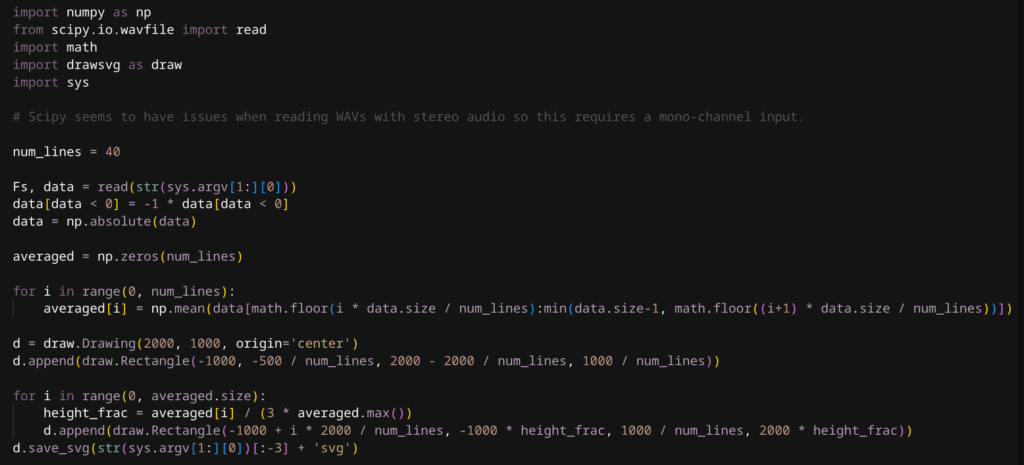

During the process, one of the students used the SciPy and DrawSVG Python libraries to generate waveform images from audio in the desired style.

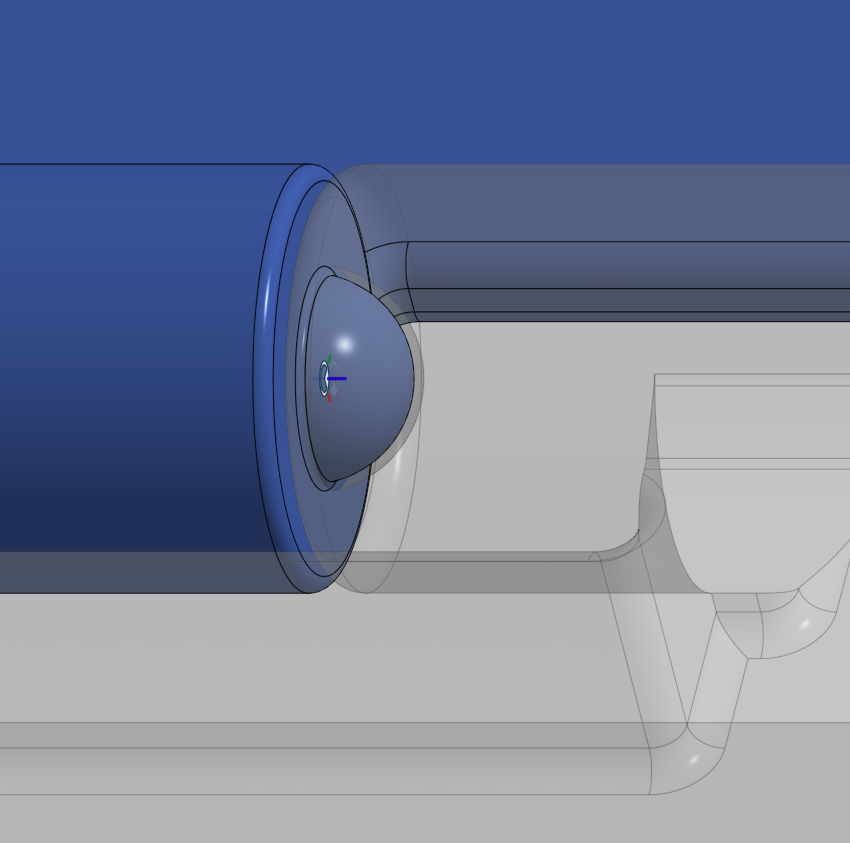

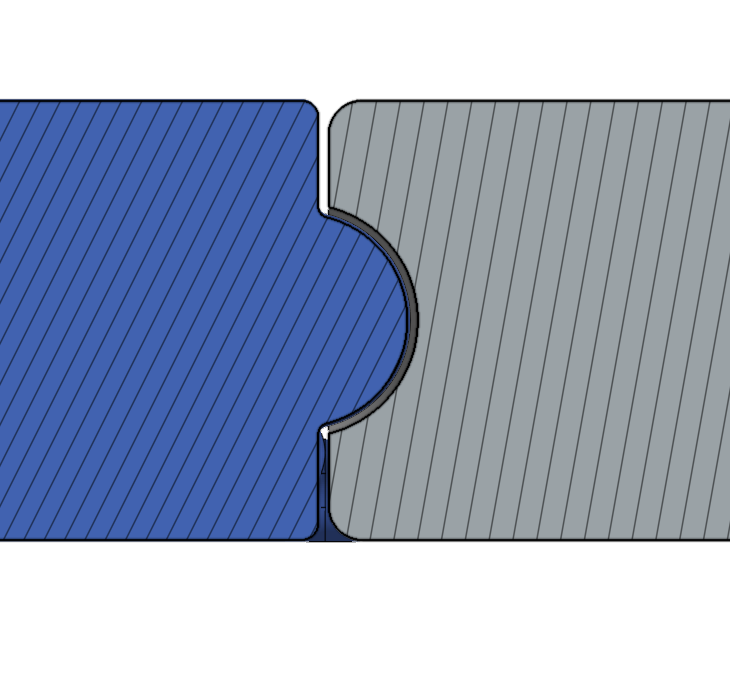

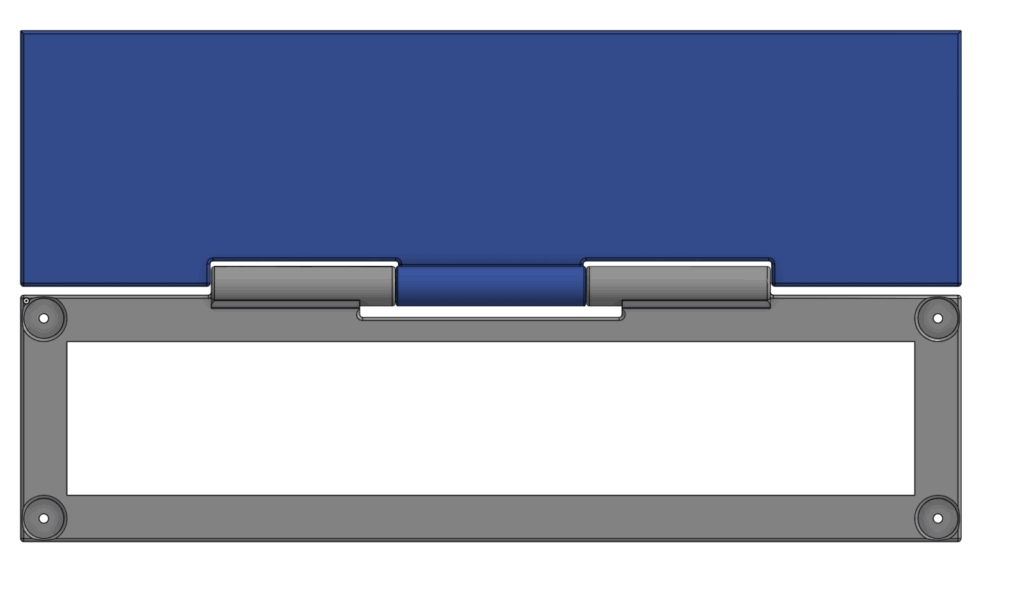

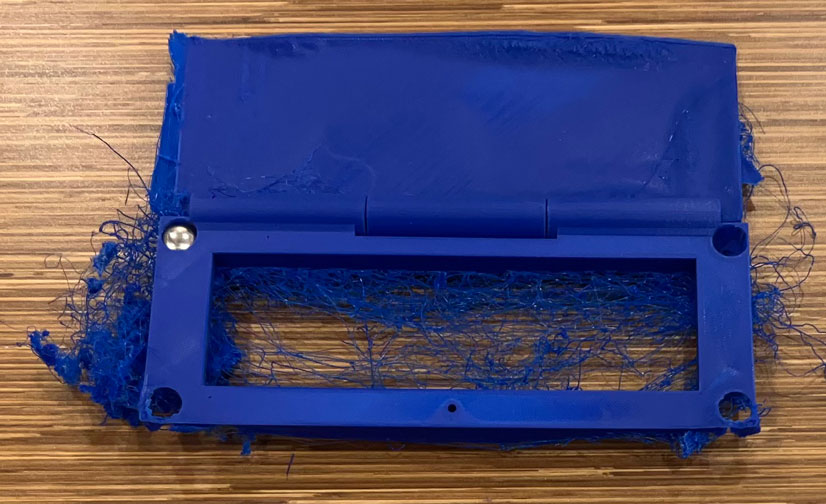

Another student created a print-in-place hinged 3d model that held the quotes.

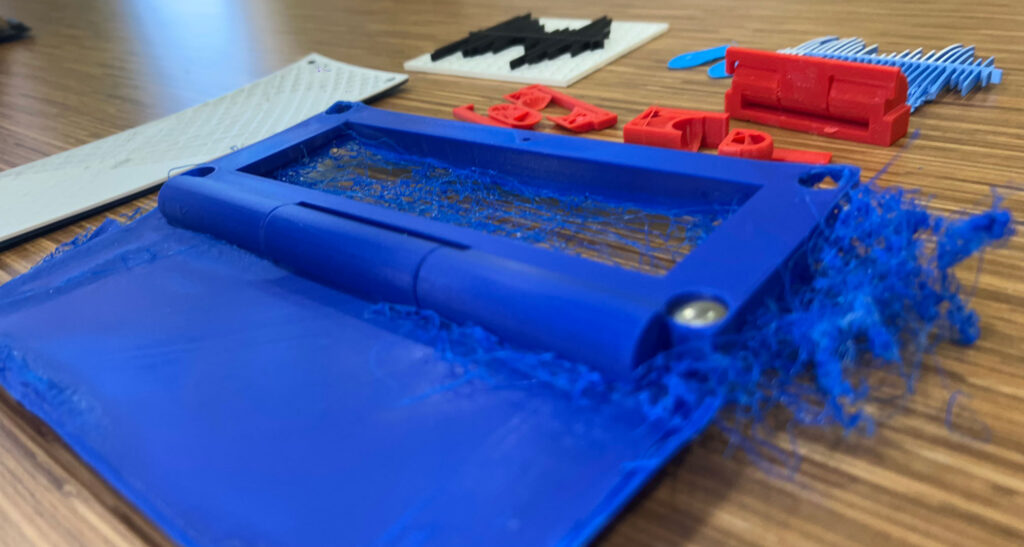

While working with an Ultimaker S5 and Bambu printer, the students were able to explore how to create 3d models that could be printed in different colors.

Along the way, as many who have explored 3d printing, a few technical issues came up.

Filament didn’t stick to the printing bed. Different 3d material was used that required different print settings. Printing a moving hinge required test prints and modifications to the 3d model.

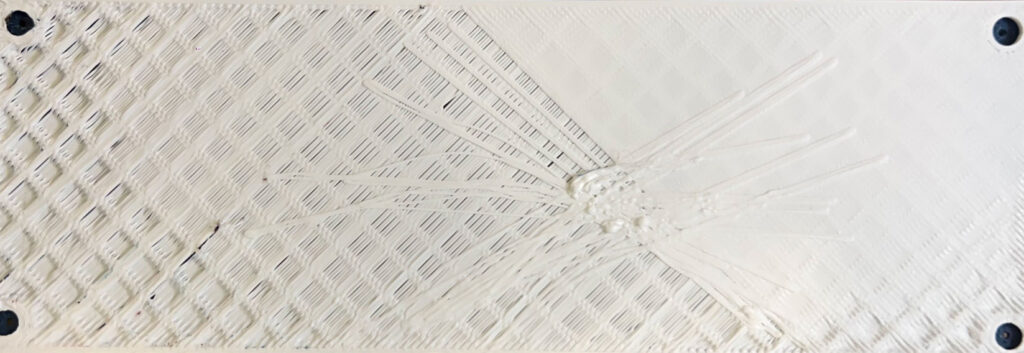

And printing small text in a 3d format can be a bit challenging; mLabbies explored having the text embossed on a surface, or embedded into a surface, both which required separate ways to design and print the 3d model.